The 3-Minute Rule for Livonia Epoxy Floor Coating

Table of ContentsThe smart Trick of Grand Epoxy Rapids Floor Coating That Nobody is Talking AboutLansing Epoxy Floor Coating Things To Know Before You Get ThisHow Lansing Epoxy Floor Coating can Save You Time, Stress, and Money.Our Detroit Epoxy Floor Coating StatementsThe Ultimate Guide To Warren Epoxy Floor CoatingWhat Does Warren Epoxy Floor Coating Mean?The 4-Minute Rule for Warren Epoxy Floor CoatingThe Of Ann Arbor Epoxy Floor Coating

Hardwood, plastic, rug, and also various other types of business flooring usually can not deal with the penalty of most high-traffic centers. Buildings with these kinds of floors generally see greater repair service and upkeep expenses, as well as increased downtime when these products require to be changed.Plastic make-up tiles (VCT) are considered by some service proprietors to be a low-cost flooring choice, which is why we see this product in several grocery store stores. If you pay $2 per foot to cover your existing concrete with VCT, you may pay the same amount each year for maintenance, given that this product weakens over time.

Sleek concrete will certainly set you back concerning 75 cents per foot to maintain and $3 to $4 per foot to set up. Over a 7 to 10 year duration, you'll really save money if you pick sleek concrete over plastic since polished concrete will not need to be replaced. An additional factor to consider is the time it requires to install as well as replace a floor.

How Sterling Heights Epoxy Floor Coating can Save You Time, Stress, and Money.

Depending upon just how much impact your surfaces get, epoxy coverings as well as brightened concrete often tend to be the most effective options for these areas. Both surfaces can hold up against extra significant and constant effect without damages when contrasted to plastic, hardwood, carpet, and various other sorts of commercial flooring. When weighing a polished concrete vs.

All, Star is a trusted concrete supplier for any kind of kind of commercial setting, with a tested track record to obtain customers the floor covering they require. Free Appointment, Ready to get more information about how All, Celebrity can aid you? Capitalize on our cost-free examination to get the ball rolling.

Warren Epoxy Floor Coating Fundamentals Explained

A full broadcast covering suggests that flakes completely cover the garage floor. Whenever you check out your floorings, the color of the finishing ends up being practically pointless, thinking about that you will not see a lot in all of it. What you see is a flake method that a lot of people seems like granite and even rock.

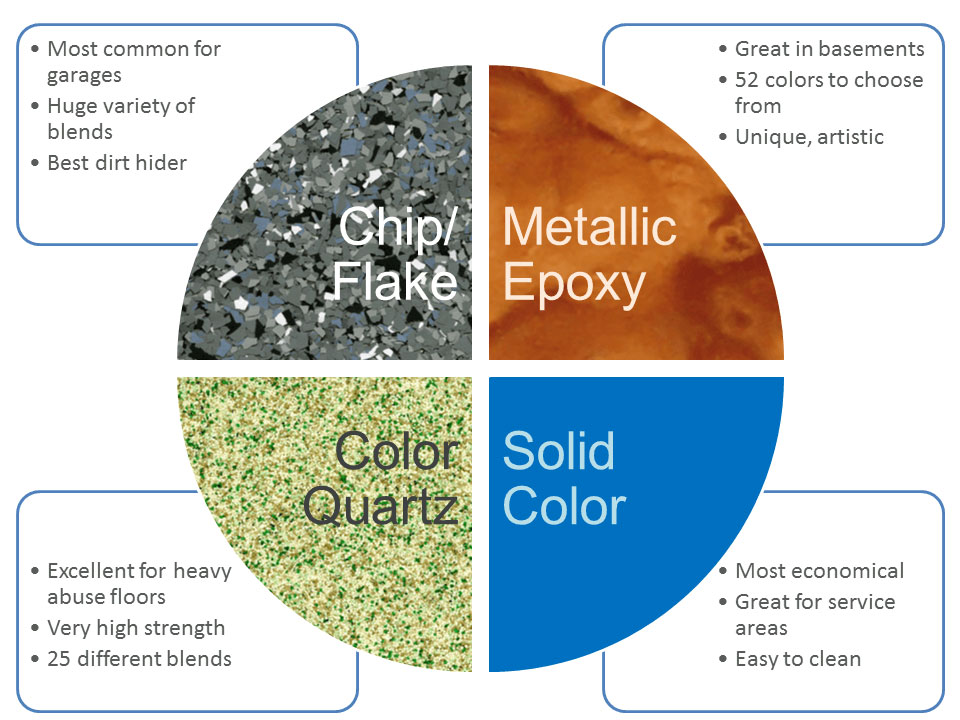

These specific flakes are for ornamental objectives as well as cover any defects of the cement flooring. Relying on which application form you select, you can pick from a variety of strong shades, and colors to personalized made shades and also include blends of color flakes that opt for whatever your style or your motif.

Allow's keep it straightforward and go over two of the most usual floor layer types, Epoxy and Polyurea. Both will certainly give your floors a glossy shine, but only one is adaptable as well as influence resistant.

Some Known Details About Grand Epoxy Rapids Floor Coating

After it remedies, a 100% solid epoxy finishing gives the concrete a shiny, tough coating. The epoxy layer will certainly chip as well as fracture over time. Epoxy is a thermoset resin, which can be used in 2 steps. It's a resin that remedies as a fluid. Epoxy Coatings can be used in enterprise zones, such as storage facilities where you need to drive a vehicle or forklift continuously.

Epoxy's treatment time can be affected by environmental variables such as moisture, temperature level adjustments, and even straight sunshine. These elements can affect not just the treatment time but likewise change the look of the coating. Epoxy is a typical, commonly utilized item that has seen its use lessen over the years.

It is very different from Epoxy resin. Polyurea is 4x more powerful as well as 98% even more adaptable than Epoxy. The material's versatility makes it durable as well as lasts a long period of time. Due to the fact that the product is versatile, it won't fracture or peel. Polyurea can also be used in extreme temperature levels. The coverings are chemically inert to oil, salt, gas, as well as other rough chemicals.

Our Flint Floor Epoxy Coating Diaries

Polyurea Coatings can be used to resurface slippery sidewalks as well as swimming pool decks. Our finishes are available in a selection of textures as well as colors. Polyurea is UV-resistant and will not yellow or discolor in sunshine. Concrete Covering tasks can be completed in a single day. You will not have to await Polyurea to cure three days.

Epoxy can be more cost-effective for temporary use; nevertheless, you need to expect to replace or refinish it within a couple of years. Epoxy Coatings usually last in between 5-10 years prior to requiring to be reapplied.

The Sterling Heights Epoxy Floor Coating Diaries

Get the most up to date updates on flooring suggestions, suggestions, storage, as well as all those great garage accessories.

Colored quartz gives a correct amount of slip resistance as well as includes an ornamental component to the flooring system. Silica sand gives this hyperlink positive grip where powerful oils and lubricants are utilized and also spilled (this kind of accumulation would be used in a maker store environment. Polypropylene spheres, plastic media, as well as glass rounds provide ample slip resistance for facilities with lighter foot website traffic and are suitable for areas in which having a quickly cleanable surface is needed they provide positive traction without gathering dirt.

There are various types of floor covering that are made from epoxy, ranging from industrial floor-coating to tiles made from epoxy-based products. Epoxy is a thermosetting polymer that produces a tough plastic image source when a liquid polymer material as well as a liquid setting chemical are combined. These two fluids are blended and the epoxy put over a base product or existing floor covering to produce a thick layer of plastic.

Not known Incorrect Statements About Detroit Epoxy Floor Coating

Epoxy flooring is a popular option for industrial applications because it develops a surface area that is invulnerable to several chemical spills and various other commercial floor covering wear. Materials such as sand, shade chips, or other hard plastic can be mixed with the fluid epoxy to ensure that the floor covering has traction. Quartz sand is usually mixed with the epoxy to create a nonslip flooring for food processing sectors.

While many individuals think of epoxy as a clear covering, many kinds of flooring made from epoxy are nontransparent. In both commercial and home applications, pigments can be combined with epoxy flooring to produce a strong nontransparent shade. Chips or huge bits of plastic in contrasting shades can additionally be combined with the epoxy to develop a marble look.

This kind of epoxy flooring is called mortar epoxy, graveled epoxy, or epoxy terrazzo. While it might be most typically used in public structures and sector, epoxy flooring is becoming preferred with property owners. There is an epoxy application for every single space in the house. Tiles made from epoxy can be stocked the kitchen, entrance or various other areas of the residence that see rush hour, and a clear epoxy layer can be put over tiles or ready wood floors.

Warren Epoxy Floor Coating for Beginners

If a property owner is interested in using an epoxy helpful resources flooring covering in a residence, he or she can contact a flooring firm or buy epoxy flooring packages from home enhancement shops. Covering Information WHAT IS THE IDEAL COVERING FOR CONCRETE? The choice of items today for finishing concrete has never been greater, as suppliers strive to satisfy market demands for newer solutions that are much faster curing, more abrasion immune, lower in dangerous VOCs and adhere better to appropriately prepared surface areas.